Available

Machining & Assembly

Machining & Assembly

nonferrous parts for the waterworks industry.

Machining & Assembly

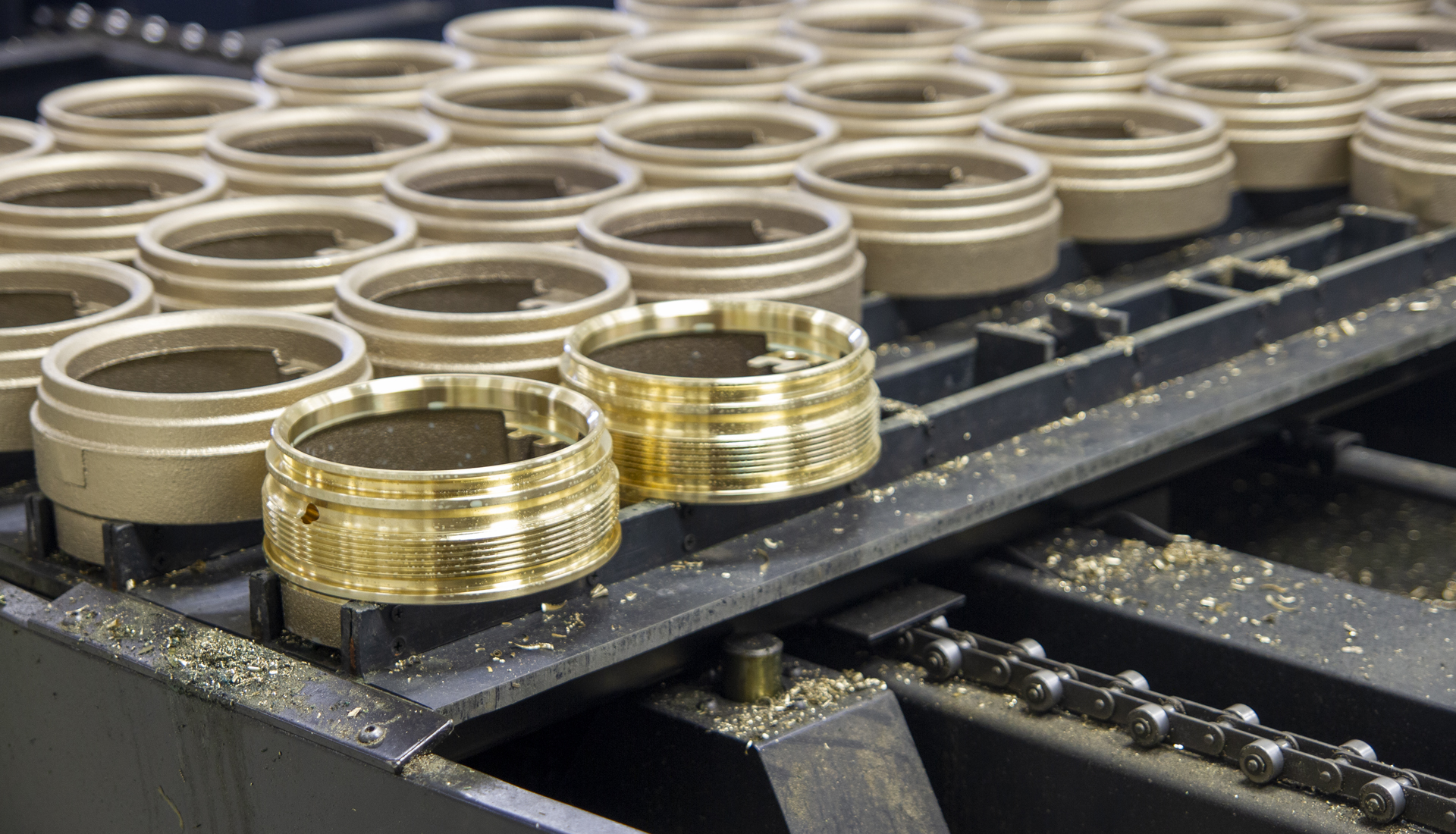

Storz Fitting

The Fire Protection Industry Since 2011

The Fire Protection Industry Since 2011

Storz Fitting

Dutchman

Welcome to

Dutchman Manufacturing Company

Founded in 2011, DMC began as a contract machining company, specializing in mid to high volume manufacturing of custom engineered, nonferrous parts for the waterworks industry. ISO-9001 certified QMS since inception, DMC utilizes highly automated, eight axis turn/mill CNC machines that are robotically tended to mitigate operator intervention. Every part is machined complete in a single set-up for optimal quality and throughput.

Appreticeship now available!

Storz Fittings

Our Storz Fittings are best in class. Built with efficiency in mind, these Storz units outperform other Storz adapters.

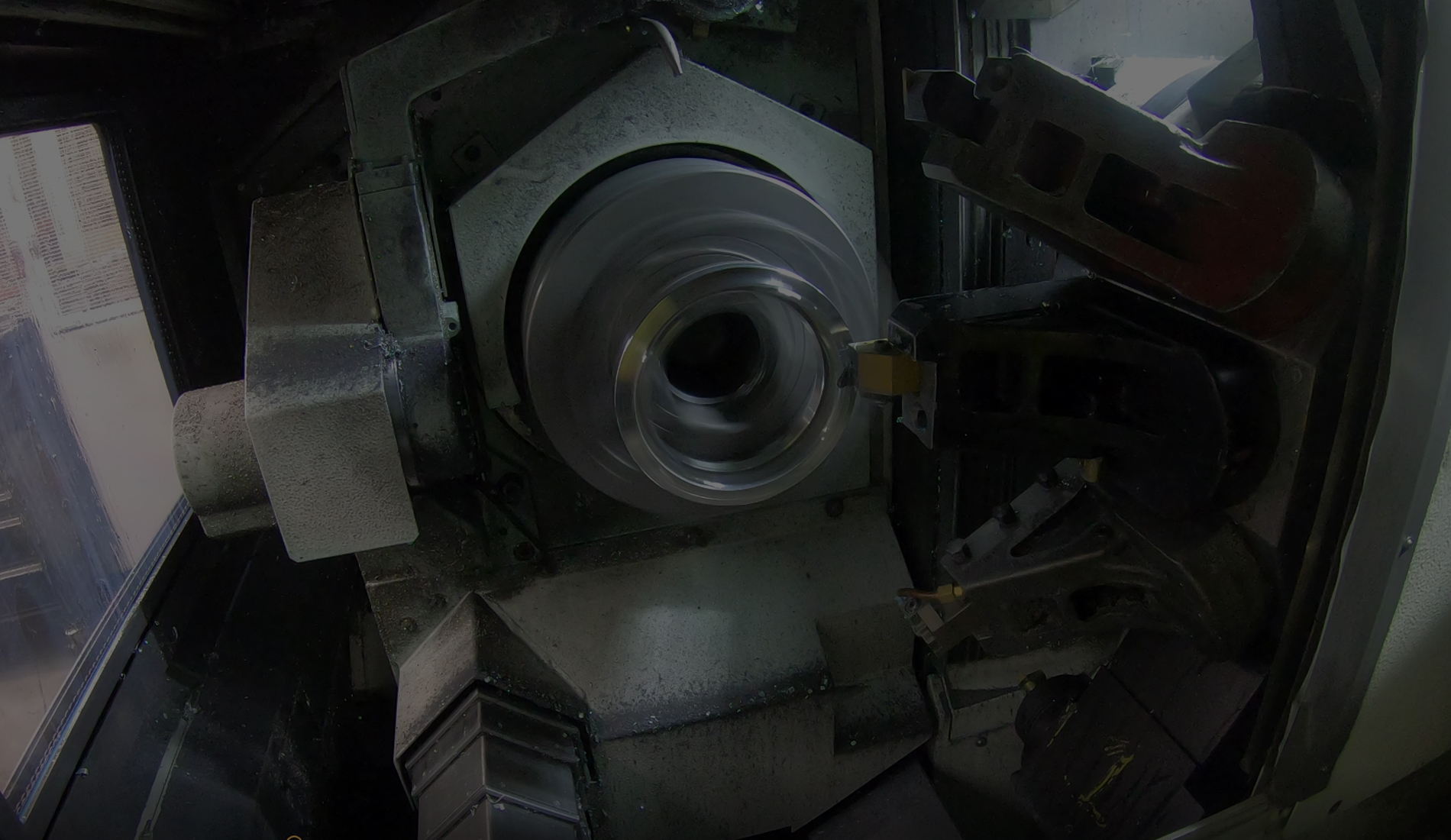

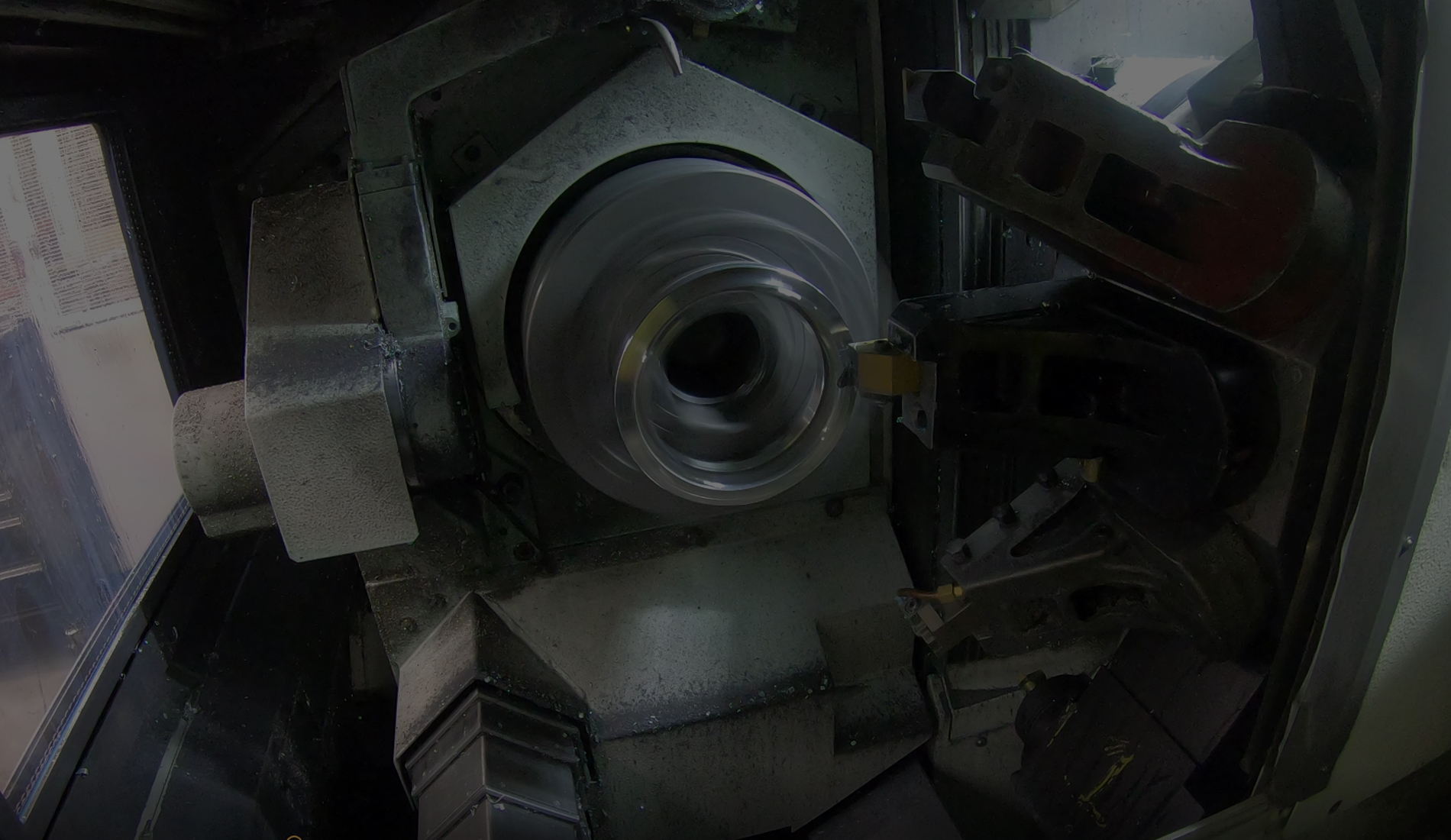

The Machine

Our automated, eight axis turn/mill CNC machines help us meet orders in a timely manner.

Who We Are

Located in Northern Lower Michigan, Dutchman Manufacturing is a focused on quality products and customer satisfaction with every job.

Dutchman

Design for

Manufacturing

Even though DMC achieves lowest cost/highest quality outcomes for the market niche’ it operates in, there is always room for continual improvement. By working with OEM engineers, DMC has been able to add features, eliminate operations or value engineer greater savings and benefits by recommending design changes for new or legacy parts alike.

When machining a complex part, it is most likely that the part will be machined on either side creating an Op. 10 and Op. 20 within the machine as it is transferred from one spindle to the next. Since throughput is regulated by the slowest cycle time on either spindle, balancing out the work load can improve cost savings or new features can be added without impacting overall production rates. Consolidating the functions of multiple parts into one, such as was done for the patented Storz fitting, eliminates inventory, assembly and set-ups thereby reducing product development, manufacturing investments and lead times. As designers/engineers strive to develop the next generation of products, DMC can help remove costs by reducing part counts in assemblies, optimize performance, function and manufacturing costs even before the blueprint is finalized.